WOODWORKING

Why should a carpenter do all the work?

Outsourcing component manufacturing is justified in large projects, or if your production capacity is already sold out. Projects can also require products or machining that would require investment in machines or workforce that will no longer be required after the project is completed.

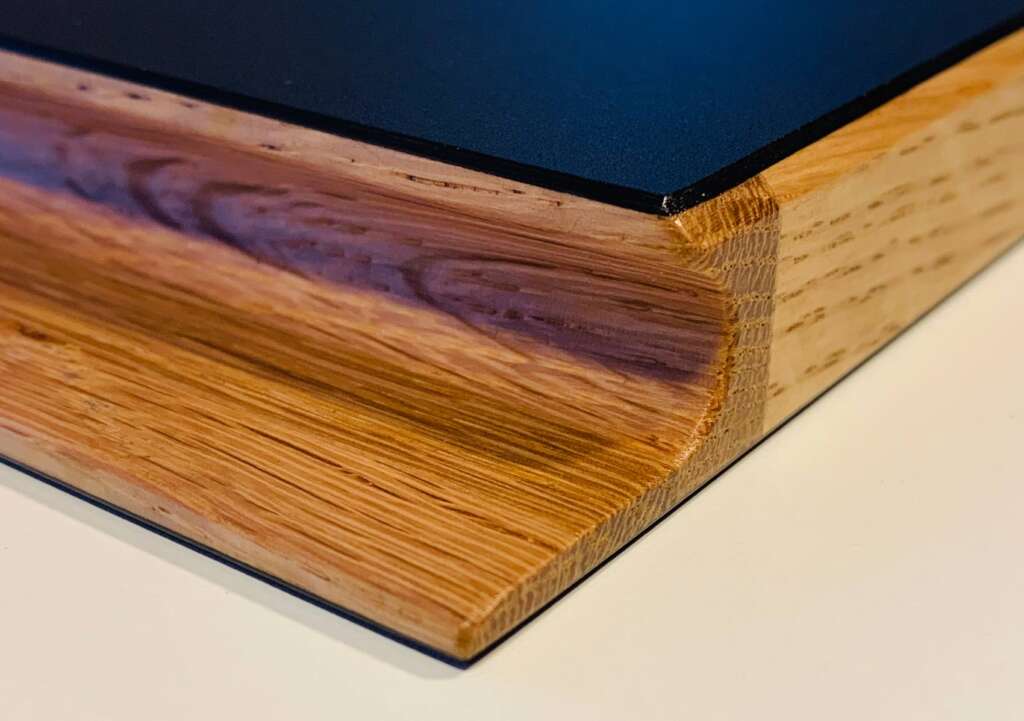

SPECIALITY EDGEBANDING

Products requiring shaped or bevelled edgebanding are challenging and require investment to ensure the cost structure of the products can be managed. Work that previously required skilled manual labour is now carried out with CNC machining.

Our current selection of machines enables us to manufacture small and large quantities of machined speciality components at competitive prices.

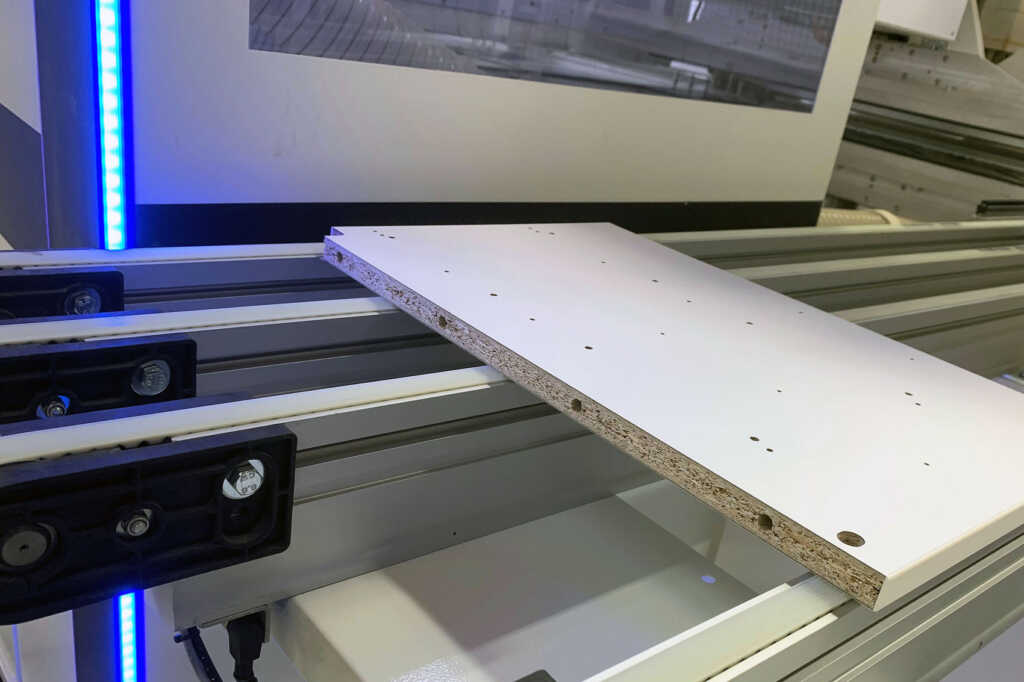

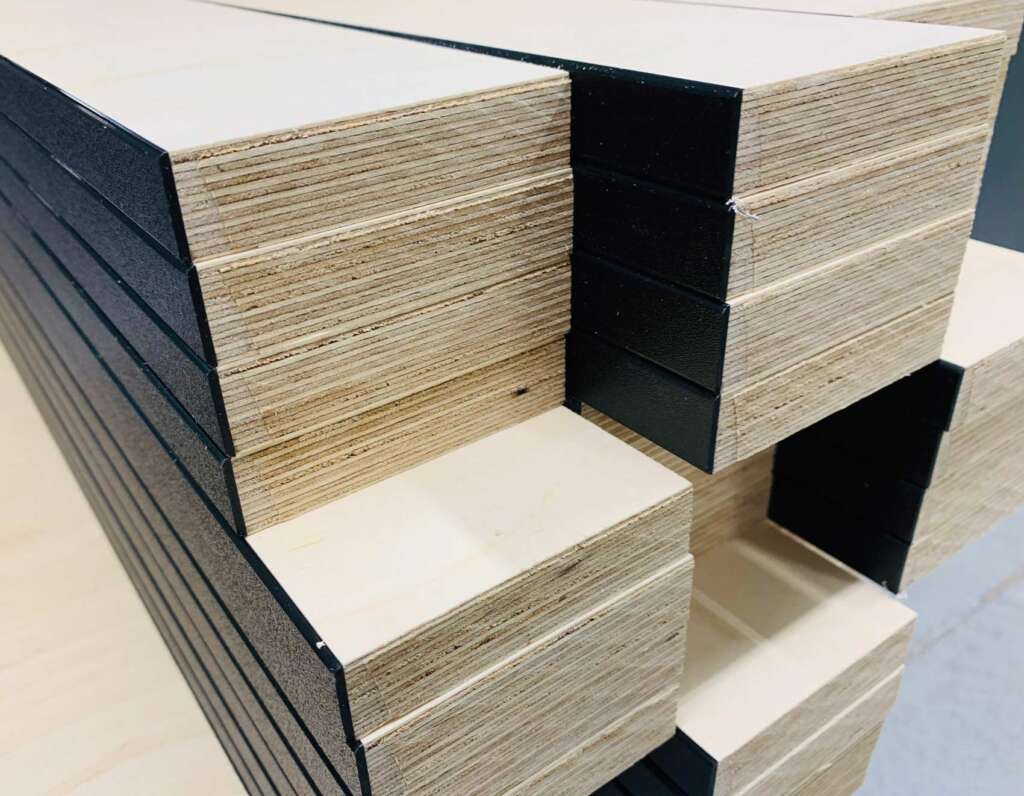

SAWING AND EDGEBANDING CAPACITY

Short-term increases in demand can result in the need for increased capacity in sawing only, for example. The labelled components can be loaded on pallets in the order requested by the customer, which makes the further processing of the products flexible and easy.

For example, sawn components are easy to insert in the manufacturing process to be edgebanded and then moved to the next steps, until the finished component is produced.

We provide the capacity you need.

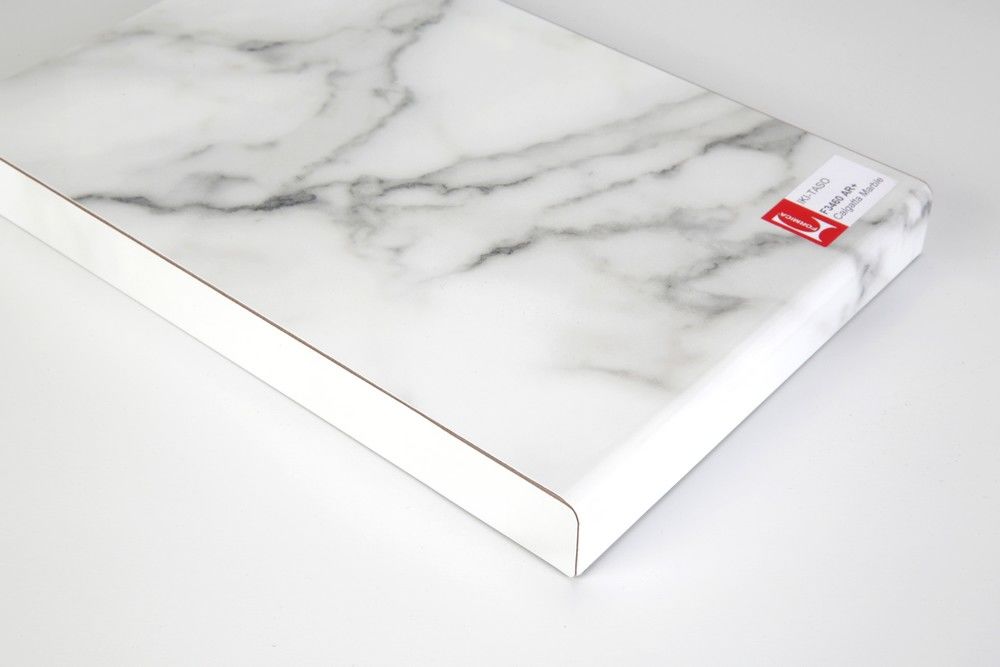

HALF-BULLNOSE AND LAMINATED PANELS

Tälli Oy provides every curved laminate product for the needs of the woodworking industry. Typical half-bullnose products include window stools, kitchen worktops, furniture doors and buffet counters.

In addition to cut-to-size products, we provide our customers with laminated panels with a variety of core options.